2-stroke vs 4-stroke small engines: Everything you need to know

2022-09-20

Table of content

small engines

Manufacturers offer two types of small engines i.e 2-stroke and 4-stroke small engines. But customers looking to wholesale may wonder what the difference is between these two small machines.

Here's all you need to know and learn about the maintenance and efficiency of each type of small engine.

Difference between a 2-stroke and 4-stroke small engine

The key difference between a 4-stroke small engine and a two-stroke small engine is that a four-stroke small engine goes through four stages or two complete revolutions to complete a power stroke.

On the other hand, a two-stroke small engine goes through two stages, or one full revolution, to complete a power stroke. This means a two-stroke small engine could potentially produce twice as much power as a four-stroke small engine but at the same time, it would be less heavy.

Let’s look at both types in detail.

4-Stroke small engine

4-stroke small engines are not only fuel-efficient but are also environmentally friendly. Let’s see the four steps of a 4 stroke small engine.

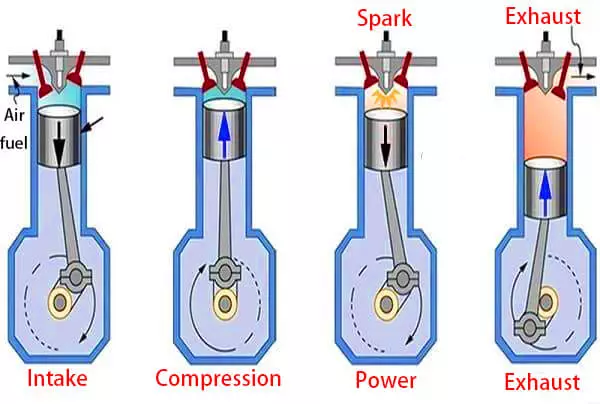

Intake: The intake valve opens, and fuel comes in with a downward stroke.

Compression: when the piston moves upward, the fuel gets compressed.

Power: After compression of the fuel, it’s ignited to produce the small engine’s power.

Exhaust: The exhaust valve opens in this step, and the exhaust gases leave the cylinder.

The working mechanism of a 4-stroke small engine

Advantages of 4-stroke small engines

There are many benefits and advantages of using 4-stroke small engines. Some of these advantages include:

Four-stroke engines do not require additional oil.

A four-stroke engine consumes fuel only once every four strokes, making it a more fuel-efficient engine choice.

These engines are built to last and can withstand more wear and tear.

Four-stroke engines produce higher levels of torque at lower revs during operation.

Four-stroke engines produce less noise and vibration during operation.

Four-stroke engines are less polluting because they do not require oil or lubricants to be mixed with the fuel.

Disadvantages of 4-stroke small engines

4-stroke small engines also have some disadvantages, such as.

4-stroke small engines contain more parts and valves, making repairs and maintenance more expensive.

4-stroke small engines require regular maintenance, resulting in increased product and service costs.

This engine design has a gear and chain mechanism that can lead to complications during maintenance.

Since it only gets its power as the piston rotates every four revolutions, this design is less powerful than a similar two-stroke engine.

Add-ons in the four-stroke design make these engines heavier than the two-stroke versions.

2-Stroke small engine

In a two-stroke small engine, the intake and compression steps are combined in the upstroke and the power and exhaust steps are combined in the downstroke.

Although the maintenance of 2 strokes is easy because of the fewer moving parts one disadvantage is that they produce less torque.

The two-step process is as under.

Upstroke: Intake and compression take place in this step. As the piston goes up, air and fuel enter the crankcase. After that, the fuel-air mixture is compressed and ignited.

Downstroke: Power and exhaust take place in this step. Once the fuel gets ignited, the piston is pushed down, and then the exhaust is expelled.

The working mechanism of a 2-stroke small engine

Both small engine types have pros and cons, and the one that's best for you depends on the needs of your application.

Although 4-stroke small engines perform well and generally last longer than 2-stroke small engines, 2-stroke small engines are lighter and faster than 4-stroke small engines.

Advantages of small 2-stroke engines :

There are many benefits and advantages of using 2-stroke small engines. Some advantages include:

The engine can operate in both cold and hot outside temperatures.

The rotational motion of the engine is uniform because one power stroke is required for each.

Two-stroke engines have no valves, making them easier to construct and reducing weight.

A two-stroke engine can work in any position because oil flow is not a concern for any valve.

A two-stroke engine is lighter in weight and requires less space than a four-stroke small engine.

As fuel and oil have to mix to lubricate the engine, it can get expensive.

The engine's design is simple due to the lack of a valve mechanism.

The engine has a significant power boost and a high power-to-weight ratio.

During operation, the engine creates less friction on the parts and improves mechanical efficiency.

Disadvantages of 2-stroke small engines include:

Let’s discuss some disadvantages of using 2-stroke small engines. Some disadvantages include:

2-stroke small engines consume more fuel, and only a small amount of fresh fuel mixes with the gases in the exhaust.

You may run into issues with purging with this engine.

Two-stroke engines have a narrower power band or speed range in which the engine is most efficient.

During operation, you may experience loud vibration or noise.

This engine type can become unstable when idle.

This engine has a shorter lifespan as it increases wear and tear.

2-stroke small engines do not burn cleanly, resulting in higher levels of air pollution than 4-stroke small engines.

They do not have a lubrication system, which is why engine parts start to wear out faster.

It uses more fuel.

Fuel easily escapes from the chamber through the exhaust port.

Two-stroke engines are always dirty due to escaping air/fuel overboard.

Small generator applications:

Applications of 4-stroke small engines

4-stroke small engines are the best choice for many different applications, such as vehicles and outdoor power equipment. One everyday example of equipment powered by a four-stroke small engine is a lawn mower.

Almost all car engines are four-stroke. Most small engines, such as those used in generators, are also four-stroke.

Other applications include

small propeller planes

small motor boats

auto rickshaws

water jet systems, etc.

Applications of 2-stroke small engines

Gasoline and diesel engines work well in two strokes, which is why they have a wide range of applications. Below you can see the applications of small two-stroke engines in various fields.

The spark plug ignition is known as the gasoline version of the two-stroke engine and is primarily effective in portable and light-duty equipment. These applications include chainsaws and motorcycles. However, when size and weight are considered, the high thermodynamic efficiency of the cycle may enable diesel compression ignition engines to be used in large and heavy-duty applications such as marine propulsion, railway locomotives and power generation.

Lawn and Garden Equipment

Mopeds

Jet ski

Small outboard motors

Radio-controlled model aircraft

Chainsaws and Jets

Stroke dirt bikes

Which small engine is better?

There is no single answer to the question of whether a two-stroke or a four-stroke is better - your choice is entirely up to your personal preference and application.

It is also important to understand the lubrication needs of each type before choosing an engine. Two-stroke engines require a mixture of oil and fuel that ignites and constantly consumes oil when the engine is running. In a four-stroke engine, the lubricating oil flows back into the crankcase after lubricating the various engine components.

The job of a lubrication system is to distribute oil to moving parts to reduce friction between surfaces that rub against each other. Friction can damage not only moving parts but also reduces the efficiency of the engine. Reduced efficiency means reduced horsepower and torque, reduced engine life, increased maintenance costs and increased emissions.

Ultimately, understanding the differences between two-stroke and 4-stroke small engines and their needs will help you make the right choice and proactively maintain it throughout the life of the engine.

Deciding which type of small engine to purchase or import at wholesale rates

If reliability is important to you - four-Stroke

For heavy-duty or extensive use - four-stroke

If you want to use them on large turf areas - four Stroke

If you don’t have too much money - two-strokes

For steep slopes or angles - a two-stroke

If you don’t like to operate heavy machinery - a two-stroke

Frequently asked questions

1) Why is it necessary to change the oil in a 2-stroke small engine?

In a 2-stroke small engine, changing the oil is important because the oil helps cool the cylinders and pistons by providing them with proper lubrication. If you don't properly lubricate the cylinder and piston, metals can melt and grind against each other, metals can move past each other and become permanently damaged, and wear out high-friction parts. and can stall the engine. Therefore, it is advisable to keep changing the oil to keep the engine running properly.

2) Are 2-stroke small engines bad for the environment?

A 2-stroke engine is not environmentally friendly. This is because these engines have ports that allow waste heat to escape from the cylinder and produce emissions.

3) Why don't we have a three-stroke small engine?

To run an engine, four main processes must be performed:

Intake

Compression

Power

Exhaust

In the case of a three-stroke small engine, you will need to select only three strokes from the above, leaving one stroke. Such an engine is not possible because it is impossible to generate power in four operations with three strokes.

4) Why is a 2-stroke small engine faster?

A 2-stroke small engine completes the power cycle in just two strokes instead of 4 strokes. Hence, it completes the power cycle faster than 4-stroke engines. 2-stroke engines also have fewer parts and are lighter. A good power-to-weight ratio and high engine rpm contribute to the vehicle's performance.

Choose BISON for your small engine needs

When deciding to choose between the 2-stroke and 4-stroke small engines, there are many things that you need to consider.

But BISON is here to help. If you’re looking for wholesale suppliers of small engines, you can contact us. We can help you with the right small engine keeping in view your needs as we are the trusted OEM suppliers of small engines whether 2-stroke or 4-stroke.

If you need more information or if you have any questions, contact us by calling (86) 136 2576 7514 or filling out our contact form today!

Final thoughts on 2-stroke vs 4-stroke small engines

We can appreciate the advantages of having a 4-stroke motor for small lawn tools like rope trimmers or backpack blowers. In general, however, we prefer a 2-stroke engine for a small motor for many of the reasons we mentioned above.

2-stroke small engines are more reliable than4-stroke small engines. There are fewer things to break, and we find them easier to start.

When you need more torque, a 4-stroke tool may be your best choice. It certainly makes more sense for a bigger motor than you'd expect to find in a hand-held air tool.

Sadly, with the current movement toward further emissions reductions and a general shift to battery-powered tools, we think the end of 2-cycle motors may be coming. Tighter emissions standards and rules could lead manufacturers to eventually phase out two-stroke engines entirely.

When this happens, we hope that outdoor power equipment manufacturers will improve 4-stroke technology to provide what the pros need when the battery power can't fully deliver the goods.