10 Main components of a generator

2022-11-04

Table of content

10 Main components of a generator

When there is no primary energy available due to emergencies, extreme weather, routine maintenance, or other reasons, a generator is used as a backup power source.

Commercial generators serve the same purpose on a larger scale as residential generators, which can power homes during a power outage.

Generators are essential to industrial and commercial facilities, as these buildings rely heavily on equipment that requires high power ratings. Due to the high power demands of commercial enterprises, commercial generators are larger, with more robust components, larger engines, and higher energy output.

Before installing a new generator, understanding how it works and what each component does is critical to ensuring its efficiency and the safety of those working around it.

How does a generator work?

Each generator component plays a crucial role in how the generator produces electricity. Understanding the basic mechanics of a generator will help solidify its ease of operation and functionality.

One of the most important things to know about any generator is that they do not produce energy. Instead, they use direct or alternating currents to convert energy into usable power.

Batteries or electromagnetic induction with a unidirectional flow are needed to generate the current in direct current (DC) generators.

Alternating current (AC) moves from zero to a positive maximum, then returns to zero. It then moves from a negative maximum to zero and back again. Batteries or electromagnetic induction with a unidirectional flow are needed to generate the current in direct current (DC) generators.

Alternating current (AC) moves from zero to a positive maximum, then returns to zero. It then moves from a negative maximum to zero and back again.

Diesel and natural gas are the two fuels used most frequently in commercial generators.

As their main fuel source, diesel generators typically have a tank attached or linked to a larger tank that users can fill with fuel.

The fuel is then put to use in the engine, which uses it to create mechanical energy by squeezing it into an electrical circuit to create a current of electricity.

For example, diesel generators start and generate electricity automatically during a power outage. It does this by converting the energy of burning fuel using the heat from air compression.

Natural gas generators are often connected to natural gas pipelines, and the utility maintains a steady fuel supply at the installation location. In some cases, the natural gas generator can be converted to use propane (LPG) and then connected to a larger propane tank on-site for standby operation.

Important things to keep in mind before purchasing a generator

a) Pollution

Diesel generators have high emissions or emissions of air pollutants such as carbon monoxide and nitrogen oxides.

b) High installation cost

Even with low fuel prices, the installation cost of a generator can be high because it requires high skills and knowledge of all components.

c) Regular maintenance

Generators need a thorough inspection to ensure longevity. Regular checks for oil changes, changing channels, and other moving parts are critical.

d) Size and weight

Generators can be heavy and can be challenging to carry around.

Main components of a generator

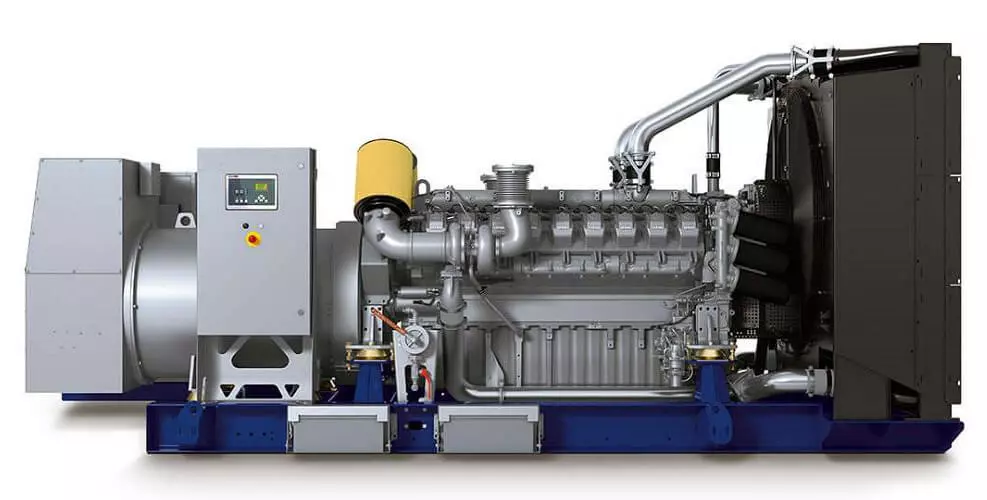

Main components of a generator

The main components of a generator are as under

1) Engine

The engine is the source of mechanical energy supplied to the generator. The size of the engine is proportional to the generator's maximum output.

There are many factors to consider when evaluating a generator engine. The engine manufacturer should be consulted for complete specifications, engine operation, and maintenance plans.

Generator engines use a variety of fuels, such as diesel, gasoline, and propane. (liquid or gas) or natural gas. Small engines typically use gasoline, while larger engines use diesel, liquid propane, propane gas, or natural gas. Some engines can also run on dual fuel (diesel and natural gas) in dual fuel mode.

2) Alternator

An alternator, also known as a "Genhead", is the part of a generator that outputs power from mechanical input provided by an engine. It consists of the assembly of moving parts encapsulated in a machine. These components cause relative motion between the magnetic and electric fields, creating an electrical current.

3) Fuel system

Typically, the tank is large enough to run the generator for an average of 6 to 8 hours. For small generators, the tank is part of the generator base. For commercial applications, it may be necessary to construct and install an external fuel tank on top of the generator frame.

Typical characteristics of a fuel system are as follows:

a) Connect the fuel line from the fuel tank to the engine. The fuel supply line delivers fuel from the fuel tank to the engine, and the return line provides fuel from the engine to the fuel tank.

b) Exhaust pipe of the tank is used to prevent pressure or vacuum when filling and draining the tank. When topping up the fuel, make sure there is metal-to-metal contact between the nozzle and the tank to avoid sparks.

c) Overflow connection from the fuel tank to the drain hose. This is necessary, so the overflow does not splash liquid on the Genset when refueling.

d) Fuel pump delivers fuel from the primary storage tank to the day tank. Fuel pumps are usually electric.

e) Fuel filter separates water and foreign matter from liquid fuel to protect other parts of the generator from corrosion and contamination.

f) Fuel injectors atomize liquid fuel and inject the required amount of fuel into the engine's combustion chamber.

4) Voltage regulator

Here we have the most complicated part of the generator. Voltage regulators are used to regulating voltage output. Simply put, it ensures that the generator generates electricity with a stable voltage. Without it, you see huge fluctuations depending on how fast the engine works. Needless to say, none of our electrical equipment can handle this erratic power supply. So this part works the magic to keep everything smooth and stable.

5) Cooling system

Cooling system

A cooling system helps keep the generator from overheating. The coolant released in the generator can counter all the extra heat generated by the engine and alternator. The coolant then carries heat away through a heat exchanger and is exhausted outside the generator.

6) Exhaust system

Exhaust system

The exhaust system collects the hot gases from combustion and discharges them into the atmosphere. In addition, it helps to reduce the noise caused by the high-velocity flow of these gases. The intake system works in conjunction with the exhaust system in a turbocharged engine to draw fresh air into the cylinders through a filter.

7) Lubrication system

This part of the generator is connected to the engine. It pumps oil into the engine to minimize the effects of sliding and rolling friction caused by metal-to-metal contact. It absorbs much of the heat generated for smooth performance and extended life of engine internals.

The primary purpose of the lubricating oil system is to circulate clean lubricating oil inside the engine while supplying it at the necessary pressure.

8) Battery

A battery is a storage device for energy provided by a battery charger. It stores this energy by converting electrical energy into chemical energy and then back into electrical energy. It powers the starter motor to start the engine. It provides the necessary extra power when the engine's electrical load exceeds the supply of the charging system. It also acts as a voltage regulator in the electrical system, which removes voltage spikes and prevents them from damaging other components in the electrical system.

9) Control panel

This is where the generator is controlled and operated. You'll find plenty of controls on electric starter generators that allow you to do different things or check specific numbers. It can include starter buttons and frequency switches to engine fuel and coolant temperature indicators.

10) Main assembly frame

The main assembly frame is needed to contain each generator in some way because this is a requirement. The generator is located there, and all the various components are constructed there. It holds everything together and can either have an open or closed design for increased security and sound absorption. In order to guard against damage, outdoor generators are typically mounted in a waterproof protective frame.

Generator parts and accessories

Generators comprise many individual parts and assemblies and can be used with various accessories. Some of these include

a) Load bank

The load bank is recommended for diesel and gas generator systems. They are designed to help test the reliable operation and current flow of various power sources before connecting the generator to an actual load. They also help diesel generators to ensure all fuel is burned during the combustion process.

b) Transfer switch

The transfer switch increases the safety of the generator. These switches help ground the generator and power equipment by providing a single insertion point for the generator. Equipment and structures can be connected to the transfer switch rather than the generator once it is up and running. An automatic transfer switch allows the generator to start automatically in the event of a primary supply failure. When power is restored, the generator will shut itself off.

c) Radiators

Radiator

A radiator helps keep your generator running within its recommended thermal limits to prevent overheating.

d) Trailer

Trailer-mounted small and large generators make transporting generators an easy task. They are helpful for mobile projects such as road or subway construction.

e) Enclosure

An enclosure can help keep your generator safe and protected from different external elements. They help with weatherproofing and noise reduction. The weatherproof enclosure is entirely waterproof, preventing water damage and hazardous situations when water seeps into the electrical system. Sound enclosures are ideal for densely populated areas where generator noise is not required.

The walk-in generator enclosure provides more space to maintain and repair the generator inside.

FAQs

1) What is an AVR in a generator?

An automatic voltage regulator (AVR) is an electronic device that maintains a constant voltage level on electrical equipment on the same load. AVRs regulate voltage changes to provide constant, reliable power.

2) Can the generator run without an AVR?

Unregulated generators, i.e. generators without an automatic voltage regulator (AVR), often cannot adequately meet the power needs and requirements of each equipment or installation connected to the generator.

3) How does a generator regulate voltage?

As the generator load increases, the increase in current causes the voltage to drop. The excitation system senses this voltage drop and increases the field strength to restore the voltage to the desired level.

4) What causes the generator to lose voltage?

Mechanical problems, such as clogged fuel injection or filters, result in insufficient fuel supply to the machine to handle the load application and can cause the engine to slow down, reducing Hertz and Volts.

Find the right generator from BISON

At BISON, we pride ourselves on providing our customers with quality and affordable generators. We only supply equipment that has been inspected, repaired, and verified, ensuring you can rely on our products.

Our knowledgeable industry professionals can assist you in identifying the generators and products that best suit your requirements and price range.

Our dedication to offering dependable, economical, and high-quality machinery enables us to meet the power generation requirements of businesses of all sizes around the globe.

To learn more about BISON, please fill out our contact form or call us at (+86) 15967890123 with any questions or concerns.