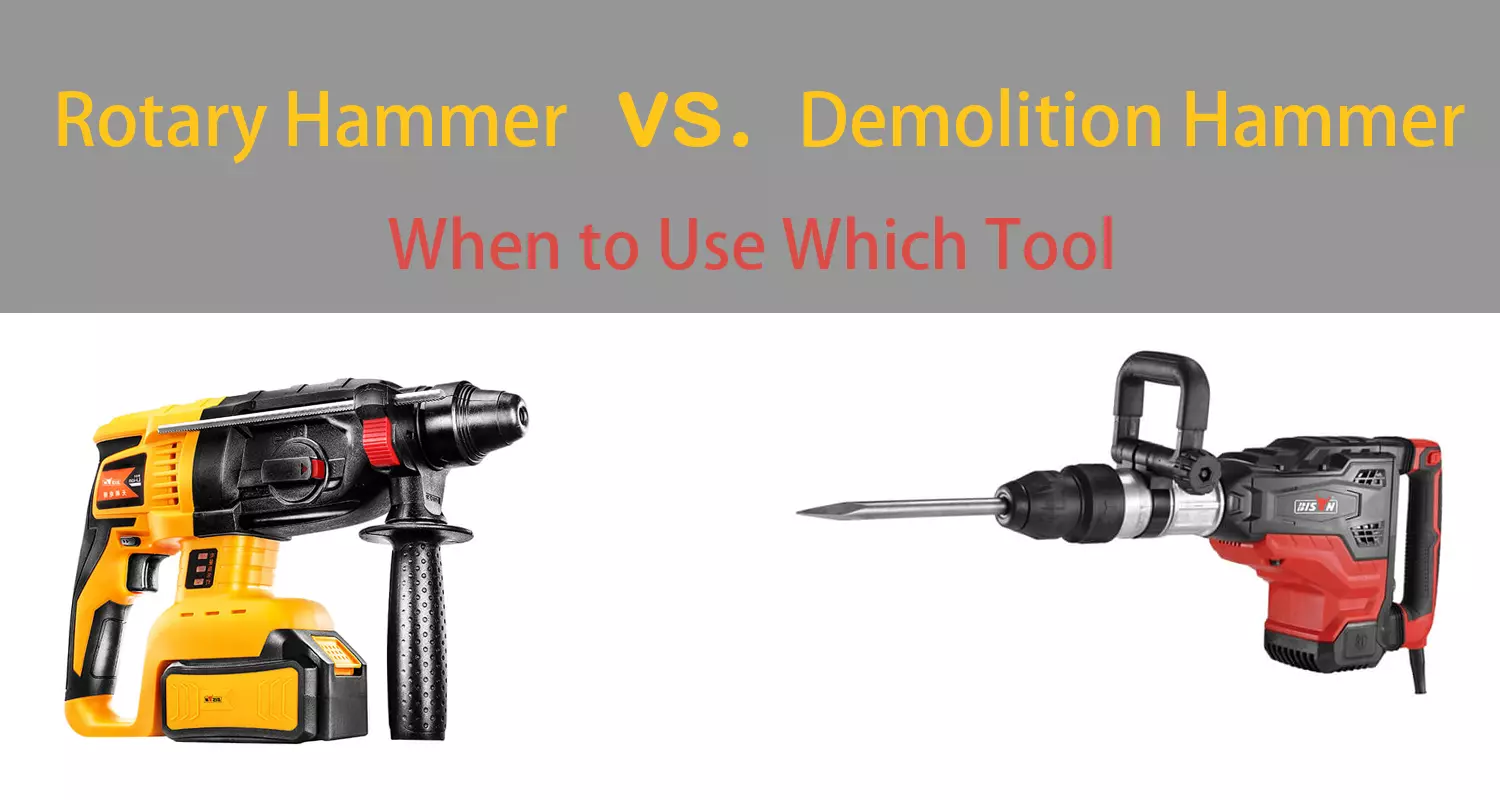

rotary hammer vs. demolition hammer: when to use which tool

2024-07-02

Table of content

In building and renovation, two essential tools often come into play: rotary hammers and demolition hammers. Although both tools share the goal of breaking rigid materials, they have specific features tailored to specific applications.

Choosing the right rotary hammer or demolition hammer is vital for anyone involved in construction or demolition tasks. This blog aims to clarify the differences between rotary and demolition hammers, highlighting their main features, applications and scenarios where they excel. You'll have a clear understanding of which tool is best suited for your needs, ensuring that your projects are executed with precision and confidence.

Rotary hammer drill vs Demolition hammer: Understanding the basics

Rotary hammer

Rotary hammer is a robust and versatile power tool designed for drilling into hard materials such as concrete, stone, or masonry. Unlike traditional drills, it works on a principle that combines the rotary motion of a drill with the hammering action, providing a powerful and efficient means of breaking through hard surfaces. Rotary hammers have a piston mechanism that produces a sharp and short hammer blow as the bit rotates. When the motor rotates, it drives a crankshaft, which in turn moves a piston back and forth in a cylinder. This piston action generates air pressure that forces a second piston, the striker, to strike the drill bit, creating a hammering action.

Demolition hammer

demolition hammer, also known as a breaker hammer, is a heavy-duty power tool explicitly designed for breaking and demolishing concrete, asphalt, or other hard materials. Unlike rotary hammers, the mechanism of a demolition hammer involves a motor driving a piston back and forth inside a cylinder. The piston compresses air, which propels a hammer-like mechanism, often called a ram, towards the chisel or breaking tool. They usually have a pneumatic or hydraulic hammer mechanism that effectively transfers energy to the chisel or point, enabling the tool to break and remove stubborn material.

Key differences between rotary hammers and demolition hammers

When choosing between breakers, it is important to understand the key differences between the two, which are as follows: power and impact energy, main features, applications, Types of drill bits and chisels:

Power and impact energy

Impact energy is an essential factor affecting drilling efficiency. Compared to demolition hammers, rotary hammers have lower impact energy, measured in joules. These hammers use a combination of rotary motion and hammer pulsation action, resulting in a high impact force on the drilling surface. Impact energy determines the tool's ability to penetrate challenging materials such as concrete and masonry, making rotary hammers particularly effective in drilling operations.

Demolition hammers, on the other hand, are designed for sheer power, especially when breaking through rigid materials. They boast high-impact energy, an essential characteristic for the controlled destruction of concrete structures. Rotary hammers are focused on delivering maximum force with every stroke and are ideal for tasks that require tremendous power.

Main features

Rotary hammers can rotate and hammer simultaneously, allowing them to drill and break materials. SDS (Special direct system): This system holds the drill bit in place for fast bit changes and excellent bit retention in tough applications. Demolition hammers are designed for pounding only, with no turning ability, making them highly effective at crushing material.

Versatility in applications

Rotary hammers exhibit versatility in their applications, making them suitable for various tasks. They are ideal for drilling holes in concrete, masonry, and stone. They are particularly useful in tasks such as setting anchors, drilling holes for pipes, and other construction activities. In addition, rotary hammers excel at light chiseling and removing tile or plaster.

In contrast, demolition hammers primarily focus on breaking and chipping away at work. They are designed with an emphasis on high impact and are designed for large demolition and construction projects such as breaking concrete slabs, demolishing large walls and removing sidewalks. They are also suitable for heavy-duty tasks involving breaking thick and hard materials. The lack of drilling capability is its only drawback.

Types of drill bits and chisels:

Hammer drills: Use an assortment of SDS-compatible drills and chisels, including pointed chisels, flat chisels and spades.

Breaking hammers: Equipped with heavy-duty chisels that are designed for breaking purposes, such as pointed chisels for deep penetration and flat chisels for more extensive breaking.

Rotary hammer vs. Demolition hammer: Choosing your right tool

Choosing between a rotary and a demolition hammer requires careful consideration of several factors to ensure that the tool you choose meets your specific project needs. Here are four key points to help you make an informed decision:

Scale and nature of the project

If your project involves the drilling of holes for installation or light chiselling work, a rotary hammer will be the right choice due to its versatility. On the other hand, if your project involves heavy-duty demolition, e.g. concrete slab demolition or the demolition of large buildings, a breaker is the right tool for the job.

Hardness of the material

Rotary hammers are suitable for applications that require precise drilling in hard materials. If the main challenge is breaking hardened concrete or masonry, a demolition hammer with a powerful hammering action is ideal for the job. The Demolition hammer is ideal for harsh and dense materials.

Precision requirements

If your tasks require a high level of precision and control, such as when drilling exact holes or performing delicate chiseling, a rotary hammer offers the necessary accuracy and versatility. When accuracy is less critical and the focus is on controlled destruction, the demolition hammer is the tool of choice.The rotary hammer provides powerful strokes for efficient material removal without precision drilling.

Cost considerations

Budget constraints may influence your choice between a rotary hammer and a demolition hammer. Rotary hammers generally have a wider price range, from about $100 for basic models to several hundred dollars for high-end versions with advanced features. Demolition hammers tend to be more expensive. Prices often start at a few hundred dollars and rise significantly for professional grade models.

Here's a BISON Tip

Example 1: If you are a homeowner renovating your house, you will most likely come across tasks like drilling pipes or removing tile. - Choose a Rotary Hammer

Example 2: You need to perform a large-scale demolition project or you are a contractor demolishing an old building. - Demolition Hammer is Essential

Caution: Whichever tool you choose, make sure that you use the correct safety equipment, such as safety goggles and ear plugs, when using it.

Conclusion

Rotary hammers and demolition hammers are both indispensable tools in construction and demolition, yet they serve distinct purposes.To make an informed choice, evaluate the specific needs of your project, consider practical examples of tool usage, and weigh the costs against the required functionality.

When choosing between these two tools, consider the type of work you're doing and your budget. A rotary hammer may suffice if you need drilling and light chiseling tools.If you would like personalised service and detailed product information on rotary hammers and demolition hammers, please contact BISON. Our team is ready to assist you with expert advice, ensuring you choose the right tool for your job and receive the best after-sales support.

FAQs

What are the common features and accessories for rotary and crushing hammers?

Chisel rotation: Rotary hammers usually come with a feature that allows the chisel to rotate for better positioning and control, but this feature is not very common in crushing hammers.

Anti-vibration system: To reduce user fatigue and increase comfort during prolonged use, rotary and crushing hammers are usually equipped with an anti-vibration system.

Depth gauge: Rotary hammers often include a depth gauge to ensure accurate drilling depth, which is vital for tasks that require accurate drilling. Breaking hammers are focussed solely on demolition and usually do not have a depth gauge.

What are the considerations when using a rotary or crushing hammer?

Both of these tools usually work with high levels of noise and strong vibration, so please be aware that whichever tool you choose, make sure you use the correct safety equipment when using it, such as safety goggles and earplugs.

Which is easier to get started with, the crushing hammer or the rotary hammer?

Rotary hammers are more compact and lighter, suitable for novice users to get started quickly. Crushing hammers are usually heavy and bulky and require a certain level of physical ability on the part of the user.