The miter saw has become a go-to tool for intermediate to professional-level woodworkers. It is a specialized power saw used to make precise crosscuts and bevel cuts in a variety of materials, primarily wood. The heart of a miter saw is a circular saw blade mounted on a swing arm that can be rotated left and right to a variety of angles for clean, accurate cuts.

In woodworking, miter saws are essential for creating furniture, picture frames, and decorative moldings. Construction professionals rely on miter saws to create frames, trim, and install baseboards. For home improvement enthusiasts, these saws are useful for DIY projects from building decks to renovating interiors.

As a professional miter saw manufacturer in China, our goal is to provide you with the knowledge and insights you need to choose the perfect miter saw for your project. In this comprehensive guide, we'll explore the different types of miter saws, their key features, and how to choose the right miter saw for your specific needs.

Types of miter saws

Types of miter saws are categorized and prioritized based on their ability to make crosscuts, bevel cuts, and sliding. A common misconception about buying a miter saw is that multiple products are needed to meet a wide range of woodworking project needs. By understanding these different types of miter saws, you can better evaluate which model is best for your specific needs.

Standard miter saws

Standard miter saws, also known as chop saws, are the most basic type in the miter saw family. It is typically available in 8-inch, 10-inch, or 12-inch blade sizes. The fixed head can only move in a vertical cutting motion and is only capable of making straight 90-degree crosscuts

Compound miter saws

Compound miter saws allow for bevel cuts, taking versatility to the next level. This category comes with a swivel arm that can rotate in different directions. Depending on the direction of movement of the blade, they can be further divided into single-bevel compound miter saws and double-bevel compound miter saws. This expands their use in more complex projects.

Sliding compound miter saws

This type adds a sliding mechanism to the compound miter saw design, increasing its cutting capabilities. It offers greater flexibility and cutting lengths than a standard or compound miter saw. The woodworker can slide the blade head back and forth across the workpiece. This type of miter saw is ideal for cutting lumber, thin masonry slabs, and whole logs (usually up to 16 inches wide, depending on the model).

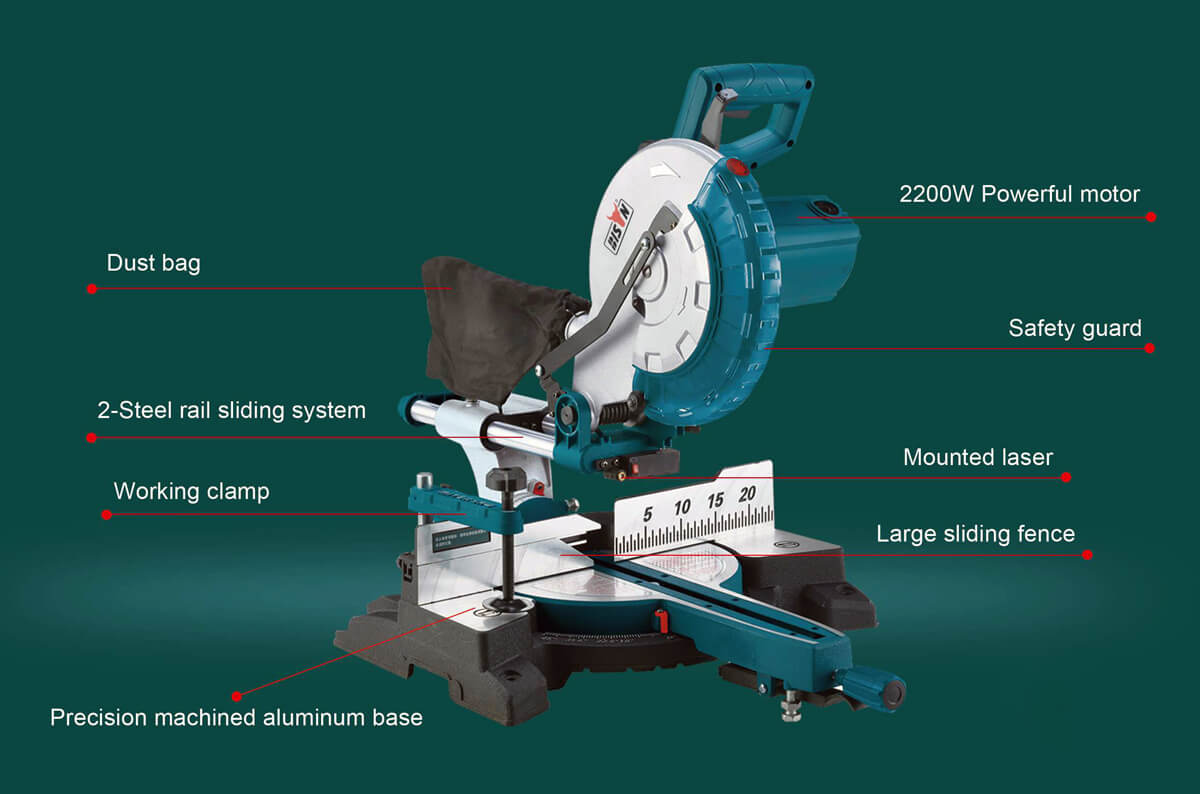

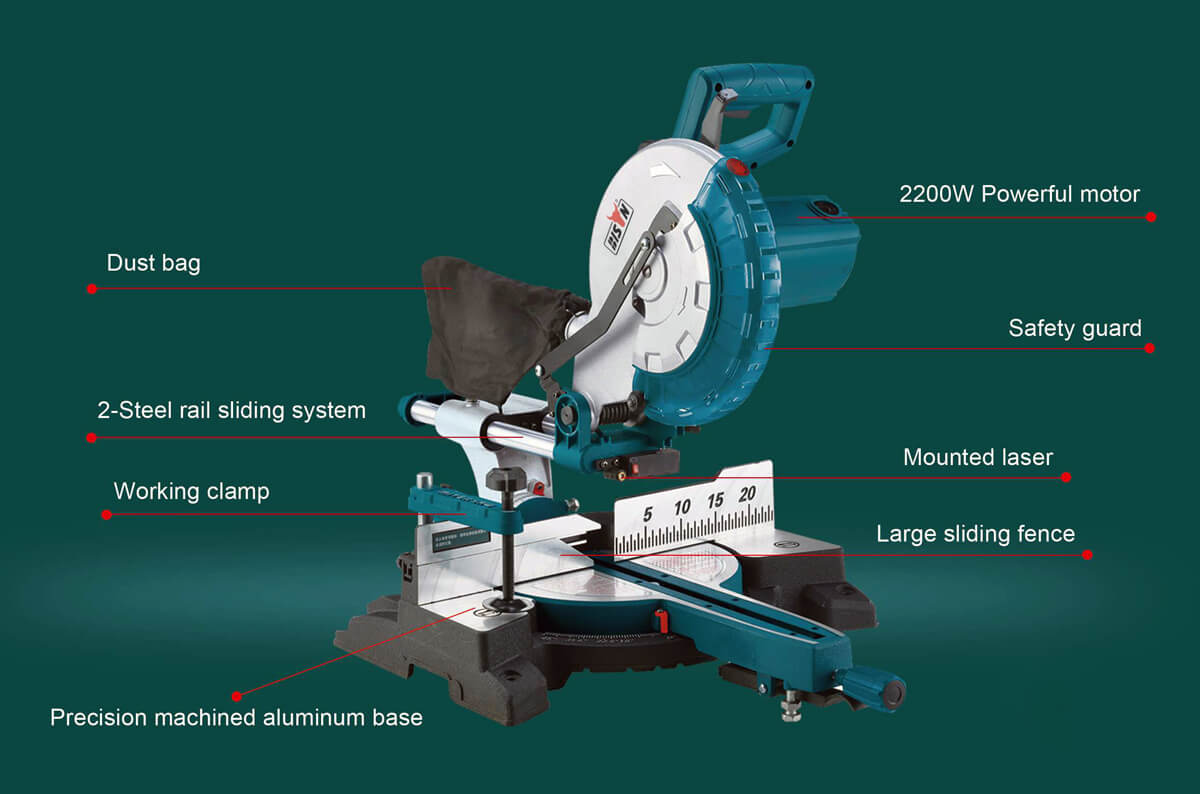

Learn about the components of a miter saw

A miter saw consists of several key components, each of which plays a key role in its function.

Blade

The heart of a miter saw is the blade, which comes in a variety of types, sizes, and configurations: typically made of high-speed steel (HSS) or carbide. Carbide blades last longer and hold a sharp edge better than HSS.

Blades with a higher number of teeth (usually 60-100) provide smoother cuts and are ideal for finishing and cutting hardwood. Blades with fewer teeth (24-40) provide faster, rougher cuts and are ideal for framing and general construction. There are also blades designed for certain applications, such as rip saw blades and crosscut saw blades, to help meet the needs of your project.

Common blade sizes include 8-inch, 10-inch, and 12-inch. A 10-inch or 12-inch blade is sufficient for most home DIY projects. A 12-inch blade is better for larger projects and cutting thicker materials. Larger blades are better for deeper, longer cuts, but may affect accuracy. Smaller blades are typically used for finer, more precise work.

Motor

The motor drives the blade and is a key component that affects the performance of the tool. Miter saws typically range from 10 to 15 amps (1,500 to 2,000 watts).

More powerful motors are essential for heavy-duty work and for cutting dense materials such as hardwoods and thick boards. For lighter tasks, a less powerful motor may be sufficient, but a more powerful motor can increase the versatility and capabilities of the saw.

Most motors have speeds between 3,000 and 5,000 RPM (revolutions per minute). But it’s critical that the blade’s speed is constant—otherwise, it won’t cut as fast, or it could burn the inside of the workpiece in the process.

Angle Adjustment

The angle adjustment feature allows the blade to rotate for precise miter and bevel cuts. Miter cuts are made by tilting the blade to the left or right of the miter saw body, usually up to 45° in each direction.

Additionally, many saws come with detents and positive stops for common angles (e.g., 0°, 15°, 22.5°, 30°, 45°), making it easier to set up the saw quickly and accurately.

Fences

Fences are vertical guides that help keep the workpiece steady and ensure accurate and safe cuts.

A taller, adjustable fence can better support larger workpieces and help align the material so that it can be cut at the desired angle. Also on the safety side, it prevents the workpiece from moving, getting stuck, or kicking back during the cut, reducing the risk of injury.

Choosing the right miter saw: Factors to consider

Power source: corded vs. cordless

Corded miter saws run on a steady power source and are typically more powerful, making them ideal for extended use and heavy-duty tasks. However, mobility may be limited.

Cordless miter saws are powered by rechargeable batteries (usually 18V or 20V), offering greater portability. A cordless model with good battery performance may be helpful if you frequently work in different locations. However, it is only suitable for site work and small tasks where mobility is critical, as power and battery life may be limiting factors. If you are considering buying a cordless miter saw, consider the average number of cuts and battery life.

Types of cuts

Crosscuts and bevels: These are single-line cuts, and standard miter saws can handle these tasks well. Choose a saw with easy-to-use angle adjustment and precision positioning to accommodate common angles.

Compound cuts: Single-bevel miter saws can bevel in one direction and are suitable for simpler projects. Double-bevel saws can bevel in both directions and are ideal for complex cuts. For two cuts on a single compound miter saw, you may have to flip the board, while on a double compound saw, you can tilt the saw head without moving the workpiece

Sliding mechanism: A sliding miter saw is a saw that slides on the cutting edge. This allows the saw to cut large areas of wood, which is much more comprehensive than a non-sliding saw. This feature is expensive and sliding miter saws are heavier because there is more equipment.

However, miter saws may not be suitable for making longitudinal cuts, you should choose a table saw or circular saw.

Budget

Entry-level models are suitable for occasional DIY projects and light woodworking. Mid-range miter saws usually have additional features such as laser guides and dust collection systems, which are suitable for regular use and a variety of projects.

Professional grade miter saws are higher powered, durable in construction, and have all the additional features such as dual bevels, sliding functions, and precise adjustment mechanisms. They are perfect for frequent, heavy-duty use and professional woodworking.

BISON is a Chinese manufacturer of custom miter saws. In addition to offering products at competitive prices, you can also adjust the optional features to further enhance the market competitiveness. Don't buy the cheapest saw. More expensive saws tend to offer more value for money but may have more features than you expect.

Weight

Weight is an important factor if you need to carry your saw around frequently. If portability is a primary concern, choose a lightweight, compact model. Cordless options also favor portability. Heavier saws are more stable and durable but can be cumbersome to move and are best suited to being stationary in a workshop environment.

Additional features

Laser guide: Provides a clear visual reference for the cut line, improving accuracy for precise cuts. Particularly useful for delicate and detailed work.

Dust collection system: Keeps the workspace clean and improves visibility while cutting. Essential for health and environmental safety, especially in enclosed spaces.

Electric brake: Quickly stops the blade when the trigger is released, improving safety, and increasing productivity by reducing wait time between cuts.

Adjustable fence: Provides better support for cutting larger parts and more accurately aligns the workpiece, which is essential for complex or repetitive projects.

LED work light: Illuminates the work area, making the cut line and material easier to see, especially in dimly lit spaces.

Why work with BISON?

As a professional miter saw manufacturer based in China, BISON proudly offers top-of-the-line miter saws to meet the needs of woodworking, construction, and DIY projects

BISON miter saws are carefully crafted with premium materials and the latest manufacturing technology to ensure durability and performance.

BISON's saws are designed to handle a wide range of applications - from intricate furniture and cabinets to sturdy construction work and home improvement projects.

Utilizing advanced production capabilities, we offer highly competitive pricing without compromising on quality.

BISON's customer service team and extensive after-sales support ensure a seamless experience for you and the end-user. We provide marketing materials, training, and technical assistance to help you succeed.

By working with us, you get a reliable supply of miter saws that meet the stringent requirements of our customers.